Before we start, a quick note on the photos. Most of these were taken at

the right time during the job, however some weren't, either because I was too

covered in grease to pick up a camera, or I clean forgot at the time. Where I've

realised I needed a picture of something I've either used a section of another

photo, or I've gone back and taken one at another time. This means that

some photos show other bits in them that shouldn't be there at

the point in the job they refer to.

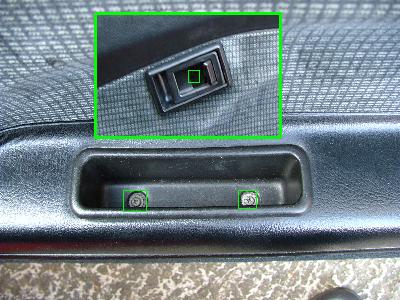

Step 1:

Undo & remove the inside door-release

handle surround, this is held on by a single cross head screw, and on a

Mk1B also remove the finger well in the armrest (two more crosshead

screws). |

|

Step 2:

Remove the triangular plastic cover on the

inside of the wing mirror. Take great care when doing this as there are

three fairly brittle clips holding this on. Prise it away from the bottom

edge first, and then be careful with the top clip, that's the dodgy one.

|

|

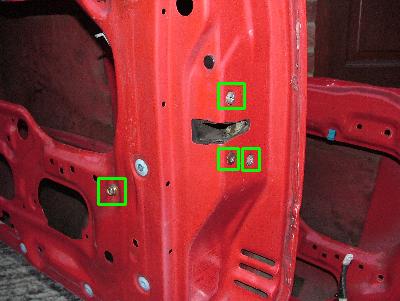

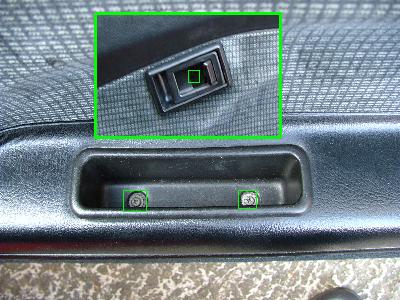

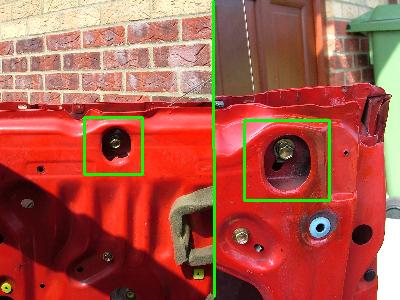

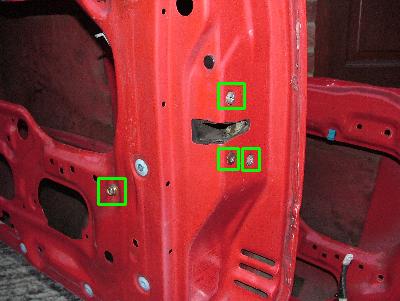

Step 3:

Remove the inner door trim, this is

secured by screws and clips. On a Mk1B there are four screws (shown in

green boxes), three through the door pocket (buried in the carpeted bit),

and one 2/3 of the way up the door at the front (behind a cap). The Mk1A

has only two screws nearer the middle of the door.

The clips (green

dots) are approximately every six inches along the bottom of the door and

up the sides. Pull the trim towards you, to pop each clip individually.

Once the clips are released the trim lifts up off the top edge of the

door.

Unclip the window switch wires before pulling the trim away from

the door. There's only about 8" of wire.

Note: picture shows

various bits that should have been removed. |

|

Step 4:

On a Mk1B you then need to remove the

bracket the finger-well screws to. This is held on by two screws. |

|

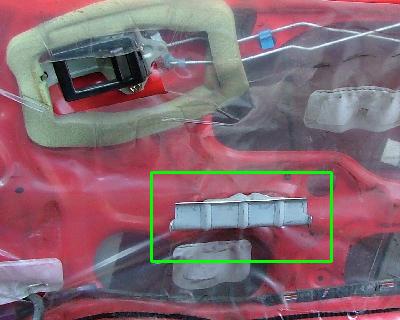

Step 5:

Undo the two screws retaining the electric

window relay (but don't disconnect it yet), and then carefully peel the

plastic damp-proofing screen from the door. Beware of the black goo they

use to stick this to the door, it gets everywhere. White spirit will clean

it off, but it can be useful to re-stick the screen after the job is done.

|

|

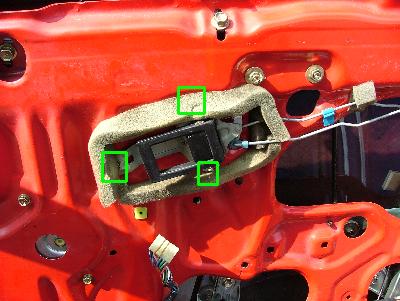

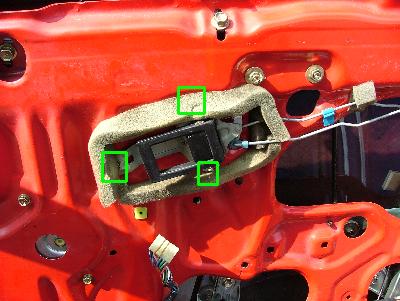

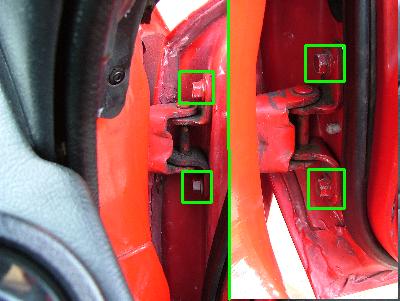

Step 6:

Reconnect the switches to the wiring

loom see insert (unclip them from the trim first) and move the

window so the nuts (green boxes) retaining the glass can be seen in the

lower door holes. The switches and relay can now be disconnected and put

to one side. |

|

Step 7:

Remove the inner door-release handle and

link rods. The handle is held on by three bolts, two of which are obscured

by the foam surround. The rods should be disconnected at the 'lock

mechanism end', nearest the back of the door. A clip secures the bent end

of the rod through the hole. Undo the clip from around the rod and rotate

it through 90 deg. The rod can then be pulled from the hole. See

below |

|

|

|

|

| This shows the type of clip, though the one's you'll be trying to

unclip won't be as well exposed as this one. |

The first step is to unclip the clip from the arm in question. This is

possible, but suprisingly difficult to do with bare fingers. Give it a go,

but if you have no luck use a screwdriver blade to push with. You won't

hurt your fingers, but there is more risk of damaging the clip. |

With the clip open, the rod can be pulled free of the clip and

whatever it is attached to. |

Optional

Step:

Undo the three nuts (See picture in Step 6) holding the window

glass to the lifting mechanism and gently rest the glass in the bottom of the

door. This isn't strictly necessary at this point, but it does give you more

room to work.

Step 8:

Undo and remove the two upper window

stops. There's one near either end of the top of the door. |

|

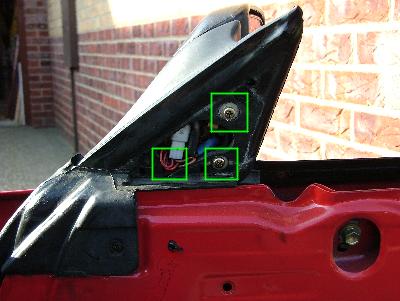

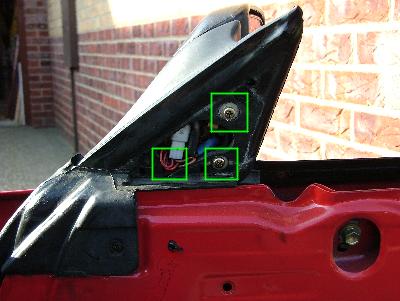

Step 9:

Undo and remove the wing mirror. This is

secured by three cross-head screws on the inside of the door. In the whole

job these were the only screws I had difficulty with. Mole grips proved

useful here. To separate the mirror from the car you need to unclip the

wiring connector located by the screws. |

|

Step 10:

Remove the rubber door seal. This is held

on by two screws at the back, a screw and a plastic stud fitting at the

front, and many plastic studs round the edge. The studs round the edge are

'T' shaped, with the bar inside the rubber trim and a ribbed peg going

through the door. It's easy to tear the rubber when removing these and I'd

recommend using a 'special tool' for the job. Mine was made from

an old carving knife I'd cut the end off and I then ground a 5mm wide slot

in the end with an angle grinder. The slot fits around the stud, so they

can be hauled out. This worked a treat. |

|

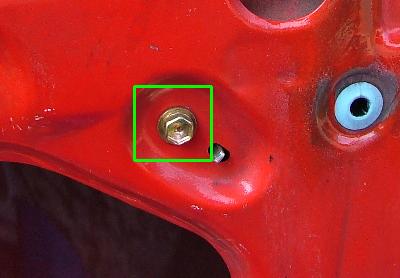

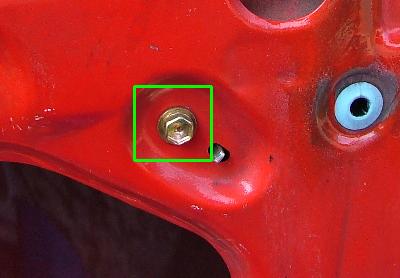

Step 11:

Undo and remove the wing mirror mount.

There are two bolts on the outside of the door, and one lower down on the

inside of the door. There is also a wiring connector to be unclipped low

down in the door (accessible through the hole the relay sat in) and a

cable clip to pop back into the door about half way up. Undo all these and

the unit can be lifted out. The bolt at the bottom will only fit through

the gap where the forward upper window stop has been taken from. (See

Step 8) |

|

Step 12:

Remove the outer black window rubber

trim. This is held on by a cross head screw at either end, and a series of

annoyingly brittle clips along its length. Take care not to bend this if

you're going to be using it again, they don't straighten well. |

|

Step 13:

Remove the two felt pads that guide the

window glass up and down. These rotate out, over the top of the door edge.

Until you've taken the outer window rubber off (Step 12) there's

not enough room to do it. |

|

Step 14:

Remove the

glass, if you hadn't previously, undoing the three nuts that hold the glass to

the window lifter mechanism. There is no need to remove any of the fittings from

the glass, they will all fit through the hole in the top of the door. Then lie

it flat somewhere, or your neighbours cat will knock it over for you.

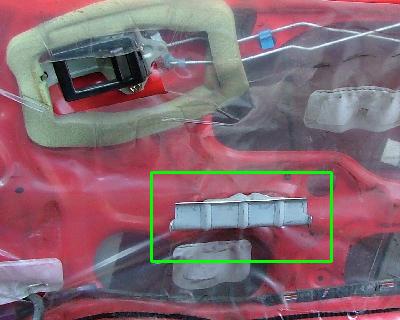

Step 15a:

Remove the window lifter mechanism. This

is held on by three bolts round the motor and three nuts for each of the

vertical guides. Remove the two plastic clips that secure the cables to

the door frame and disconnect the wiring connector that is accessible

through the relay hole. The clips and connectors are best undone first as

they can be tricky to unclip once the rest is unsupported. |

|

Step 15b:

Once everything's undone the whole unit

can be manhandled out of the large hole in the door. It takes some

jiggling, but that's how it comes out. Take care with the cables, they

don't work well if kinked. |

|

That's the worst of it done....

Step 16:

Remove the lock linkage pivot. One bolt

to undo and a rod to disconnect. |

|

Step 17:

Remove the door handle. The handle itself

is secured with two bolts, and it's linked to the catch by two more rods.

The door opening clip works the same way as all the others, it's just

scaled up.

Photo taken after links to lock had been removed.

|

|

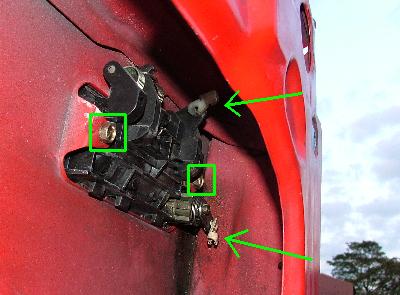

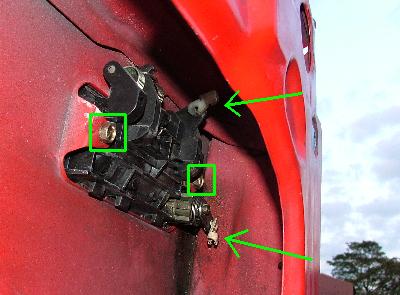

Step 18:

Remove the door latch. This is secured by

three screws through the rear edge of the door, and one bolt through the

inner edge of the door. There is one final wiring connector to unclip and

then the catch can be lifted out. |

|

Step 19:

Remove the wiring. The wiring bundle

comes through a hole in the front edge of the door. The hole has a plastic

insert that needs to be removed. Unclip the loom along it's length. The

wiring can then be pulled out of the door through the hole. All the

connectors and clips do go through it, there is no need to cut the wire.

|

|

Step 20:

Removing the rubbing strip, if you need

it. We're back to my favourite special tool, the carving knife. The strip

cuts away from the door quite easily, don't let it drop away from the door

as you're doing it though. It is worth taping the ends down after you've

cut in from them, because if the strip falls and bends the backing can

crack and delaminate, rendering it useless. Mk1A's have particularly tough

adhesive for the first inch or so, making them harder to cut free, the B's

are easier. |

|

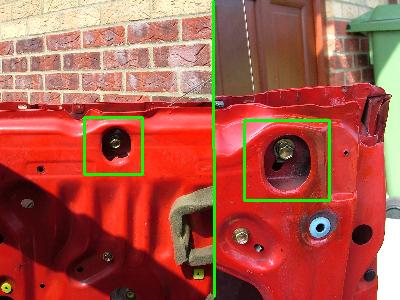

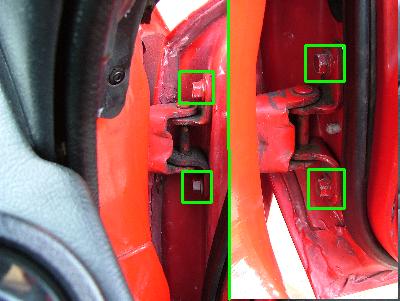

Step 21:

Remove the retaining bar. The retaining

bar needs to come off before the door can be removed. Lift the pin out of

the joint at the car end, there is a retaining clip underneath you'll need

to 'persuade' off first. The main unit is then unbolted from the door by

removing the two nuts that fasten it to the edge of the door. It can then

be taken out from inside the door, through the hole the window relay sits

in.

Note: picture shows various bits that should have been

removed. |

|

Step 22:

Remove the door. Starting with the bottom

one, remove the bolts securing the hinge to the door. As you undo the last

one you'll need to support the door, or get someone else to. But at least,

at this point, it's not that heavy anymore.

Note: picture shows

various bits that should have been removed. |

|

Step 23:

Cup of tea.

Re-fitting is, as ever, the same thing backwards. Take the chance to

hoover the bottom of the new door out, and spray liberally with Waxoyl (or your

preferred treatment). Setting up the window though, needs a little more

explanation:

Setting Up The Window

Assuming you've got everything re-attached with the window glass bolted to

the lifters in a central position (there are marks on the brackets to indicate

where this is), this is how you do it.

- Before you put the plastic sheet on, temporarily reconnect the relay and

switches so you've got control of the window again.

- Wind it halfway up.

- Whilst pushing the glass out so it just touches the outer window rubber,

adjust the felt guides (Picture Step 13) so they now just touch the

inside of the glass.

- Next fasten the upper glass stops (Picture Step 8) in position,

(start low) and wind the window up. Move the stops up as necessary until the

window reaches the right position. (The leading edge should line up with the

wing mirror mount, and the top should be true to the door seal with the door

closed.) This might take a few goes to get right.

Now, the Mk1 window is designed to open and close with a slight twisting

action at the end of its stroke. This helps it make and break the seal with the

rubber more easily, and gives you a tighter fit.

To get this to happen, now that the glass stops in the right place, adjust

the front bracket (where the glass is fastened to the mechanism, picture

Step 6) until the front edge of the glass hits its upper stop with the rear

end still 5-10mm lower than its stopper. There is a cunning spring-loaded

'slack' section in the system that will allow the rear to continue to rise that

last bit after the front has reached position, twisting the glass into place. As

the window is lowered, the reverse happens. The rear edge drops away from its

stopper first and then the front will start to move.

Levelling a Door:

These cars are getting old, the doors have seen a fair bit of use and the

pins are starting to wear. Really the only solution is to replace the hinges, as

there doesn't seem to be the facility to adjust the position. I have

'cheated' slightly though, in order to cure a door where the latch didn't

cleanly strike. You might want to do the same if you're having to swing the door

closed hard to 'bounce' it onto the striker. All I did was fit a couple of

washers between the lower hinge and the door, which has the effect lifting the

back of the door slightly. (In addition the door will end up that much nearer

the back of the car, which affects the gaps between the door and the panels,

but not much.) The door is so long in relation to the vertical distance

between the hinges, that there's a lot of height to be gained for very little

backwards movement.

Notes on door types:

Mk1A doors and Mk1B doors are not identical, but it's not

disastrous. The door off a B has four extra holes in it for fittings used to

secure the trim panel. Consequently you can use a Mk1B door on an A with no

difficulty, but to put a Mk1A door on a B you'll need to make the extra holes

and fit the plastic fastenings in. Unfortunately these holes are square, so it's

out with the files. I found laying the new door trim in place and marking the

spots through the trim was accurate enough for the positions. Drill them out

using the largest drill that will fit through the final square hole, and file

out some corners.

In either case keep hold of the plastic fittings that fasten your

door trim. Even though the Mk1B door has the holes for the Mk1A

fittings, it doesn't have the same ones, and the pop studs round the edge are a

different size from the A to the B. So, before you sling your old door, strip

all the plastic connector bits off it.

Uses for old doors:

- Sledging

- Novelty rabbit hutch roofs

- Taking up space in the garage.....

- Tripping over

- A conversation point with your other half, as in "When are you going

to do something with that...."

Karl Thomas, SE Region

Back to repairs index page

Back to main page