ENGINE REMOVAL - PAUL WOODS

Foreword

I often get numerous emails or phone calls from owners

wanting to have a go at removing their MR2 engine and gearbox themselves. Now

although I really donít mind helping MK1 owners at all, I thought it was about

time someone did a step by step pictorial guide on how to do this in the most

efficient way.

Personally I remove a MK1 engine in around 2 hours but I do this type of thing everyday. For

the novice I'd expect it to take a long weekend or an afternoon for the more

experienced. Either way this guide should prove useful to someone.

Preparation

A garage is preferred to do this but not essential, and

all that matters, if it is done in a garage, is that theres at least 4ft of

roofspace above the car allowing for the rear of the car to be jacked right

up. Also a good selection of tools is needed but mainly 10mm, 12mm, 14mm and 17mm

spanners will undo just about everything. A good 2 ton plus trolley jack is

essential and a pair of axle stands. Also if theres no engine hoist above the car

for lifting the car up a 4ft long 3Ēx4Ē timber is essential for placing

across the crossmember on the front bulkhead of the engine bay for spreading the

load so that a 2 ton trolley jack can lift the whole car safely.

METHOD

Safety always comes first, at no time should you attempt to crawl under the car with

just a jack holding it, sounds like common sense but it needs to be said. Ok

first thing to do is disconnect the battery terminals, no other wiring must be

removed until this is done first.

The two 10mm bolts

on the battery clamp are undone and the battery can be removed - for safety

always remove the earth clamp first, a swinging spanner on the positive terminal

touching the car body can cause a nasty burn, and in extreme cases a battery

explosion - not good!

Next all of the

yellow circled bolts or clips are undone and the plastic box removed. The red

circled areas show the idle up VSV which must be unplugged and its vacuum pipe

removed from the inlet on the blue circle. The intake tubing can now be removed.

The reversing light

switch is now unplugged and the two 12mm nuts removed from the thermostat

housing together with the gearbox earth strap and the two hoses circled blue.

The remaining

heater and radiator hoses are removed from the thermostat housing together with

a brown temp sender plug. On the right the two yellow circles roughly depict

where two 12mm bolts must be removed from the driveshaft shield and the speedo

cable circled blue is also unscrewed, this may be seized so lube it generously

with wd40.

Next the three

bolts holding the throttle linkage are removed and the throttle linkage bar

prised off, the linkage can be tucked behind the battery tray, also circled blue

the two 12mm bolts are removed to free the fuel lines from the coolant

housing. On the right the electrical plugs are removed from the coolant temp

sensor and engine bay fan probe. Also one of the gear change cables is removed by

taking out its split pin.

The two 12mm bolts

holding the clutch slave cylinder onto its bracket can now be undone but this

won't come off until a larger bolt is removed from under the car. On the right the

expansion bottle is removed.

Next the brake

servo clip is removed and the pipe taken off. Also the two large clips on the

coolant filler point hose are removed and this hose removed too.

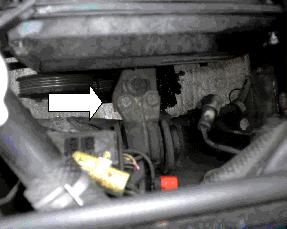

Now the MAP sensor

can be unplugged and its vacuum hose removed from the manifold. On the right the

TPS sensor is also unplugged.

Now remove the

rocker cover breather pipe and also start disconnecting the distributor

wiring/coil pack and oil pressure sender switch wire that is directly below the

distributor.

Unplug the HT leads

and remove, now undo the two 12mm bolts holding the distributor in place and then

slide it out. It may need to be rotated left and right when doing this as they

are a tight fit.

The remaining

coil/amplifier wiring plugs need to be disconnected along with an earth

connection. There should be nothing else electrically connected in this area now.

You

can now undo the two 10mm bolts that hold the fuel pressure regulator onto the

fuel rail, once this is off the fuel line can be tucked behind the battery

tray. Also disconnect the alternator thick white feed wire, unplug the

mulitplug from its rear (blue) and undo the 12mm bolt on the alternator

adjusting arm. Remove the 14mm bolt from underneath the alternator and remove it

from the engine bay.

You arenít able

to see the bolts in question but there are three 10mm bolts on the inlet

manifold, two of them secure a fuel line and the wiring harness to the manifold

while the third is an earthing point, remove them all. Also unplug the four

injector plugs, you may want to sticky label these with tape numbered 1 to 4 from

right to left as they can get mixed up during refit.

You can now remove

the cold start injector banjo from the fuel rail (yellow) and remove the fuel

return line fitting from the end of the fuel rail (not shown), unplug the

electrical plug to the cold start injector (blue). The three 12mm fuel rail bolts

can now be removed.

Remove the fuel

rail completely. Now you can start to remove the engine wiring harness, start at

the distributor and lift it off feeding it through the inlet manifold eventually

lying it all over the passenger side of the car.

On the right theres

five bolts holding the inlet manifold on, theres also four underneath the

manifold and also a manifold steady bar thatís bolted to the manifolf and also

the block, remove all of these and lift the manifold off the engine. The engine

will actually come out with the manifold left on but its much easier with it

removed.

Remove the two water pipes that feed the waxstat on the throttle body, the manifold is

now ready to slide off.

Now the t-vis rail

can also be removed, sometimes this comes off with the manifold. If you are

refitting this try to look after the gaskets. Now that the manifold is off you

have good access to unbolt and remove the alternator, again this would come out

with the engine but its easier if its removed. A 12mm bolt on the adjuster and

two 14mm on the pivot bolt.

Undo all six nuts

on each driveshaft and tie each shaft up out of the way, I use thick cable ties

secured onto the strut tops for this but anything will do. Undo the exhaust

middle hanger bracket and remove.

Remove the three exhaust to manifold nuts (yellow) and the two front torque mount 14mm

bolts circled red. On the right remove the rear torque mount via the

two 14mm bolts on the chassis (yellow) and the two 14mm bolts on the gearbox

(red).

With the engine

supported either by jacking trolleys underneath or by a hoist from above, undo

and remove the right engine mount, one 14mm bolt from above and two from

underneath. Undo the two from underneath first as a safety measure. Undo the 17mm

bolt that passes through the right hand engine/gearbox mount.

Gently lower the engine/gearbox to the ground taking care not to foul anything on the

way down. Now place a jack under the front engine bay crossmember supported by a

large piece of 4x3 to spread the load. Slowly jack the car up off the engine

until thereís enough height to pull the engine out from the rear.Under no

circumstances must you rely on this jack and beam alone before attempting to pull the engine out.

Make sure a couple of axle stands are in place beforehand.

Finally pull or walk the engine out from underneath the car, its quite light and swivels

around easily. The refit procedure is an exact reversal of this article. I hope it

proves useful to someone attempting this for the first time. If you have any

queries at all then please ask, advice is always free.

Paul Woods.