SPECIAL SERVICE TOOLS - SST's - LOW COST DIY VERSIONS

As the title suggests, this article is biased towards those

afflicted enough to have DIY tendencies!

Anyone who has ever visited a Toyota Spares Dept. will know how expensive

their spare parts are. Well it's even worse for any of their Special Service

Tools (designated as 'SST's')

These SST's are tools tailor-made for working on specific Toyota components,

usually to allow quick disassembly and replacement of these components to a

larger sub-assembly.

Luckily, not all of them are absolutely necessary as they are primarily

designed to simplify and reduce Toyota workshop job times.

Usually, improvisation with the standard tools as typically found in the

average home garage will achieve the desired result but this process tends to

consume a fair bit of time.

Obviously, the more times a given job is done, then the more time that

improvisation is going to take.

So, for a rarely done job there is really not much incentive for having an

SST improvisation should suffice.

For a much more frequently done job however, the time and 'fiddling on' of

improvisation multiplies up and starts to becoming irritating, the SST starts to

become desirable except for the Toyota cost!!

Fortunately, some of the more commonly useful tools can be duplicated quite

cheaply by almost anyone with access to basic metal work fabrication facilities.

Now I realise that a fair number of members, such as who get their cars

serviced professionally will have absolutely no need for any SST's and that is

perfectly fair enough, just jump straight on to the next article.

Nevertheless, there is still a fair proportion of members who do some or all

of their own maintenance and this sort of DIY article is intended to act as a

form of encouragement. The series will cover items from small and simple to

perhaps large, but all cheap!

To illustrate this without putting people off, this issues tool is small, a

doddle to make and exceptionally useful on those tricky rear disc calipers.

Later issues will move up through the range to a full blown engine/gearbox

stands (the standard commercial versions can only take the engine, my version

allows full engine/gearbox matching.

So, for simple starters this articles DIY SST is a 'Rear disc piston

retractor tool'.

This might sound a bit complex or even intimately painful but it really

isn't!

First though, what would be the use for such a tool to justify making one?

Well, for one it is very useful when changing pads.

To change these pads the piston has naturally to be retracted to make space

for the new (obviously thicker) replacement pads. However, unlike the front

brakes the piston cannot be 'simply' pushed back.

This is because the handbrake linkage is screwed to the rear piston, so the

only way it can be retracted is by rotating it.

I realise this probably sounds a bit confusing so perhaps the following

diagrams might help out -

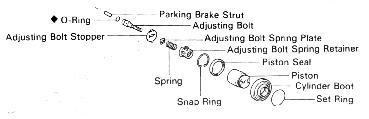

First of all an exploded view of the rear brake assembly -

Now even I would have to admit this is not Toyota's best understood sketch as

it tends to show so much as to be altogether too confusing. To make it

marginally less confusing just concentrate your focus on the following - parking

brake crank, adjusting bolt and piston.

Together they form a nearly solid linkage, its actually a bit more

spring-loaded complex than that, to explain it will require a separate article.

Until then just take my word for it on the apparent complexity of the design,

the main point to understand is that the piston has to be rotated to retract it.

This in itself is a bit of a problem - an SST is often needed! This is perhaps

not totally true, if your car has brand new (refurbished) calipers and handbrake

cable it can be done with long nose pliers. In better than average condition

then pliers will suffice. In average condition it's a struggle and after that

itís impossible!

The piston nose design is just not really designed for pliers as can be seen

in this more detailed exploded view -

This is the Toyota SST -

To overcome this I made a simple 'twin peg' turning tool, shown as -

- only this tool could shift it!

Fabrication is quite simple for those with metalwork and welding facilities,

if there is a demand I will produce a manufacturing sketch.

For the majority without such facilities, well I could probably knock them up

to order but it would cost ca £25 at cost.

For those with a need but not enough to buy, I will lend it out willing for

free TO CLUB MEMBERS ONLY - but only for 2 weeks (just like a library) on

receipt of a large deposit, fully returnable on return. (P and P at borrowers

cost.)

More SST's are to come, any requests/suggestions?

ALAN JONES