DESIGN AND MAINTENANCE NOTES - STARTER MOTOR SYSTEM.

This article is intended as the first of a series of items

covering the main systems of the car, with the aims of providing a brief guide to:-

- design features

- good and bad reliability aspects

- hints and tips on key maintenance jobs

This sounds simple enough to do but the hard bit is to balance technical

content with 'readability' - too little detail will leave 'holes' which might be

important to those doing their own work - but too much could be too lengthy and

just plain boring to others.

There are quite a lot of subtly important aspects which are not covered in

any of the manuals - to include them in one article could fill many pages of

this magazine - to the extent of spoiling its readability.

So, I have deliberately kept this article brief, but with hints on pitfalls

to watch out for. Fuller details can then follow in a later issue - or possibly

on the website.

System design details

The system design is utterly conventional – the ignition switch feeds the

starter motor relay which feeds the solenoid on the pre-engaged starter motor –

just the same as is fitted to millions of modern cars and is well proven.

The circuit diagram is ---

At a detail level it is the starter motor itself which is different to most

other makes - the MK1 uses a reduction gear between the motor and the drive

pinion. This allows a better motor performance albeit at the cost of slightly

more complication.

It also makes the assembly less bulky than normal - allowing Toyota to tuck

it out of the way - almost to the point of hiding it! More than a casual glance

is needed to spot it - lurking underneath the exhaust manifold. There is

negligible maintenance access from above, and the compactness plus working on it

from below make life a bit harder than normal.

An exploded view of the starter is--

The relay is located in the nearside junction box near the front of the

engine compartment.

Reliability

The system is well - proven and reliable. I rarely get queries on it, and it

seems to be good for 100k miles+. In my case the motor started showing slight

signs of weakness after 112k miles, so I ended up changing it. The following are

brief notes on changing it --

Removal

This is not the most convenient job - it needs to be done from underneath

with the n/s rear jacked up and propped.

1) Make space to be able to maneouvre the motor out downwards. Removal of the

exhaust front pipe would be ideal, but too much hassle & not essential. The

plastic undertray really does need to come off - about half a dozen M6 bolts to

remove. These are often seized & rounded - I've had to drill the odd one

out.

2) Disconnect the battery negative lead. Whilst I would normally avoid this

if at all possible, the risk of not doing so is a bit high - one of the leads on

the starter motor body is a permanent unfused lead from the battery positive.

This has to be undone with a spanner, and any accidental contact to earth with

this spanner will cause a significant short which could burn the wiring harness

out - or worse. There is just not enough clearance in this area to take those

sort of risks.

The unfortunate downside of disconnecting the negative lead is that the ECU

will lose its 'learnt' adaptive memory. This is another story for another

article - but is not the end of the world - it reverts to the factory default

setting when connected up again. What it does mean is that it will then take a

couple of dozen typical journey cycles to 'relearn' and re-optimise the ignition

timing etc. - a minor nuisance. Any radio security coding is obviously also

activated.

3) Remove heatshield - this is not essential at this point but it makes the

motor assembly a bit smaller for getting out. It is held by one 6mm bolt -

remove with a 10mm 3/8" drive socket.

4) Slacken the two mounting bolts for the motor. These are both 14mm across

flats -the lower one is easily visible but the upper one is tucked away under

the clutch slave cylinder.

5) Remove the bolts - usually hand spinnable. Keep motor supported by free

hand - its not unduly heavy.

6) Undo the 2 motor connection leads. (These cannot be undone with the motor

in position as they are too close to the block to get at.) The permanent

positive is a 12mm A/F nut, the ignition switch live is a plastic plug. The

latter has a bayonet catch on it which has to be depressed with a screwdriver

blade to release it.

7) Manoeuvre the motor out past the bottom of the exhaust manifold - its not

unduly tight for clearance.

CHECKS

Having got the motor out there are a limited number of checks that can be

done - the brushes, commutator, armature, coil and solenoid resistance. However,

apart from brush changes none of the parts are readily user replaceable. Even a

brush change is of limited value as the commutator will be worn.

All in all, given the time needed to remove and replace the motor, I elected

to fit a reconditioned unit - available from motor factors such as Partco,

Halfords etc. (Not cheap at £90 - but that`s also the going price for a 'common'

unit such as for a Metro or Corsa.)

One point to note if getting a reconditioned unit - check there is a threaded

hole in the body to mount the heat shield. Mine didn't have one so I

'improvised', but it took a couple of hours.

REPLACEMENT

Just reverse the steps for removal, take care that the motor sits squarely

home on its seat when bolted up. Listen carefully when first starting to check

the meshing sounds OK - if not re-check the motor unit seating.

For those that are feeling really conscientious, after a couple of days

re-nip up the mounting bolts as a precautionary measure.

This gives a brief flavour of the system and working on it – I`ll endeavour

to write a full description for a future issue.

ALAN JONES

Starter Removal and Rebuild

After just hearing a click when turning the key to start the

car, I had to rebuild the starter. Here's how you go about replacing a couple

contacts and the brushes, which should bring your starter back to life.

Removal of Starter

1) Raise and support the rear of the car on jack stands.

2) Disconnect the negative cable from the battery.

3) Remove the under-carriage cover (bunch of 10mm bolts). You should then

have ample room to work with the starter. It is right between the front motor

mount and the exhaust manifold.

4) Remove the heat shield from the starter (10mm bolt).

5) Remove the two 14mm bolts on the other side of the transmission.

6) Disconnect the black plug (Terminal 50) on the end of the starter.

7) Slide the starter out of the tranny, toward the passenger side of the

car.

8) Twist the bottom up toward you, so that you can access the 12mm bolt

holding the battery wire to the starter (Terminal 30).

9) Turn the starter counter-clockwise. So that the gear part faces the front

of the car.

10) Then pivot the starter down, so that the gear side comes right down

toward you. It should then slide out of the car pretty easily.

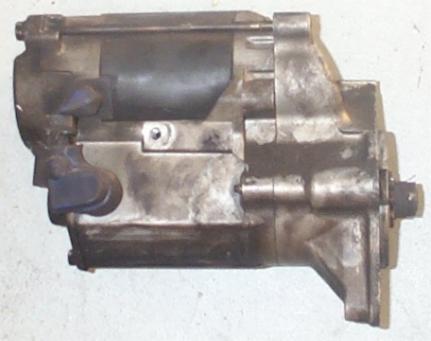

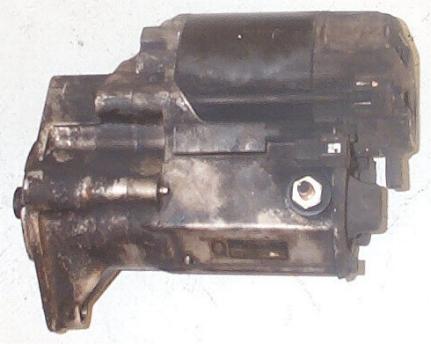

11) Just some pics of the starter.

Removal of Copper L-shaped Contacts

12) Remove the two long, skinny 10mm bolts (blue) holding the field frame and

armature to the starter housing. Pull the field frame up and off. The armature

may come off too with the frame. If so, be prepared for it to fall as you remove

it.

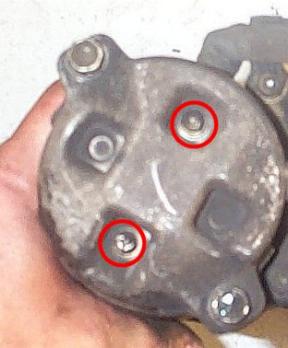

Then remove the three 8mm bolts (red) holding the cap on the magnetic switch

end.

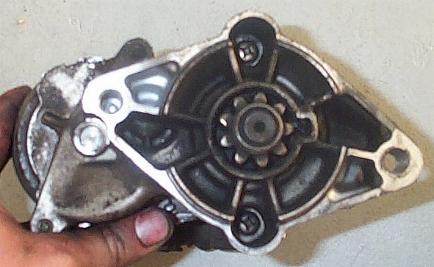

13) Here's what you will see after you remove the magnetic switch end cap.

The plunger in the middle pushes down to engage the gear on the opposite end.

When it does this, the copper ring on the plunger comes into contact with the

copper L-shaped contacts on either side of it. Those are what we are going to

replace.

14) Remove the plunger by pulling it straight out. Be careful of a skinny

spring on other end of the plunger. Keep it in a safe place.

15) Remove the cap from Terminal C and remove the 12mm nut holding its ring

terminal on.

16) Remove the various nuts, washers, & insulators that are holding the

L-shaped contacts in place. Take note of the order of how you removed

everything. Be very cautious of the one bolt that has a washer that is connected

to a wire leading down to some windings. The wire is quite brittle, and if you

break it, you will need to solder it back in place. It's no big deal though,

just need a solder gun and a small piece of solid copper wire.

17) Here's the plunger & the copper contacts. Notice the roughness of the

underside of the plunger's copper ring. Sand/file it down, so that it is smooth

again.

Here's a comparison of the new contacts to the old. You can see how it has

been worn away by the spinning each time the car is started.

18) Just pics of the empty starter housing. You can see I broke that

connection on that washer I was speaking about earlier.

Install New Contacts

19) You can purchase the new contacts at a local starter rebuilder. Just look

in your Yellow Pages for one. I've read a few people on the MR2 message board

have only been charged a buck for both contacts. Well the guy I went to wanted

$9 for 'em. Didn't feel like running all over town so I went ahead with them.

Install the bolts & contacts the opposite of how you removed them.

Noticed the new wire soldered in place.

20) Place the spring and plunger back down in the cylinder.

21) Install the cover and the three 8mm bolts.

Inspecting Brushes

22) If you want, since you have the starter out, you can check the condition

of the brushes. Remove the armature from the field frame. Clean the dirt/grime

off the windings with some fine sandpaper.

23) Remove the 2 Phillips screws holding the cap to the field frame/brush

holders.

24) You can now see the brush holder 'standing' off from the field frame.

Remove the 2 brushes from the holder that are keeping it in place. They are held

in by spring clips, just take a skinny screwdriver to get them out. You can now

inspect the brushes (sand/file if needed) and check their length. BGB calls for

a minimum width of 10mm. Replace if necessary.

25) Place the 2 brushes on the field frame back into the brush holder. This

may take some time and finesse with a screwdriver...

26) Insert the armature into the field frame. The small coil goes toward the

brushes end. Work the brushes over the bearing and onto the coils. This may take

a few minutes since you only have 2 hands, trying to work all 4 brushes at the

same time.

27) May as well clean the bearing surface and the underside of the field

frame cap. Apply a little bit of fresh grease to the bearing surface.

28) Watch out for the armature falling out from the bottom, and place the

field frame cap over the brush holder. Line up the holes and tighten the 2

Phillips screws.

29) Turn the field frame assembly over and clean up the bearing on the other

side of the armature. Apply fresh grease. Clean up the starter housing where the

armature gear fits into and install it into the starter housing. Make sure the

holes in the field frame cap line up with those of the housing. Install the two

long 10mm through bolts.

30) Connect up Terminal C, and tighten the 12mm bolt. Starter is now ready to

go back in the car.

Installation of Starter

31) Installation is exact opposite of removal.

A lot of steps, but a real easy project. Removal and installation of the

starter should take 15 minutes tops. Keep track of all the bolts, screws,

washers, etc. when taking the starter apart.