RESTORATION SNIPPET – CAM COVERS

This is part of my seemingly never ending N/A restoration project and done by total accident!

Although I’ve always admired the super looking cam covers of some

members at meets the likes of Billing etc. it always struck me as a priority 3

job, ie a bit cosmetic, below bodywork and mechanicals etc.

However I sort of tripped over this job by accident after removing the

cam covers to inspect the camshafts condition and clearances.

On doing this I found that the internal surfaces of the covers (some call

them cam-boxes) were a bit gummed up with black tarry residues of old oil.

Nothing terrible, in fact about what I’d expect with an engine that’s done

100k miles, and most of that probably on ‘previous generation’ mineral oils

with relatively poor anti coking qualities and even less in the way of effective

detergents. The cam covers are prone to collecting this crud being relatively

cool compared to the engine internals they act as ‘condensation spots’. (At

least it wasn’t the dreaded white ‘mayonnaise’ – a sure sign of water in

the oil and possible evidence of head gasket failure.)

This sight decided me to clean them up at least internally. The reason

for this is that I will be using ‘current generation’ engine oils when the

car is finally finished, either full or semi-synthetic.

These have highly detergent properties (as do modern mineral oils albeit to a slightly

lesser extent) which runs the risk of loosening any tarry lumps, good in theory

but not so clever if they get swept into an oil way and start blocking it.

Bear in mind that the internal oil ways are quite narrow and can have abrupt changes in

direction, all the better for getting blocked all too easily!

This is especially crucial at the ‘top-end’ of the engine – the

flow to the camshafts is always critical to both their journal bearings and the

camshaft lobes and cam followers. The latter have to endure both high speeds and

heavy rubbing stresses, a conflict for any oil.

The oil flow to this area could in fact be beefed up but manufacturers

don’t as it can create local flooding problems as the gravity flow path back

down to the sump can only be made so big.

In addition, any excess oil flying around in the exhaust cam box could well get

sucked into the throttle body via the crankcase breather hose (a black hose

about 13mm outside diameter.) This would rapidly gum up the throttle butterfly

and more importantly create havoc with the exhaust emissions.

Just to illustrate this the baffles in the exhaust cam box are both extensive and

complicated, they are there to stop oil spray from getting into that breather

hose. The inlet cam box has by comparison no breather and no baffles.

The oil

flow is deliberately kept towards the low side to avoid emission problems. This

is fine when everything is new and clean, but

any blockage to these supply oil ways is not good for the engines health. Even a

marginal reduction in oil flow to the cams will all too quickly result in wear

damage.

So I decided to get rid of this black gunge and oh what fun I had!

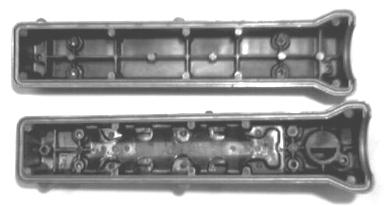

A photo of the box internals follow, they are really quite complex with many

internal ribs, done for both oil baffling and sound attenuation (aluminium is

far more resonant than steel and so needs more stiffening to prevent it from

‘drumming’.) You can see there

are many internal surfaces which are ‘nooks and crannies’ and that’s only

the inlet cam box!

The exhaust cam box is a veritable labyrinth, the pressed steel oil

baffle is a real ‘crud-trap!’

I briefly contemplated temporarily removing it for cleaning access but it is so heavily riveted on to the aluminium casting that I decided

discretion was a better bet. (It could be flush bolted back on I suppose, but

the thought of them or the baffle coming loose at high revs makes the flesh curl

and the wallet shrink!)

So the cleaning, and only talking the internals in this bit. To set the

scene simple scraping is a ‘dead-duck option’ as it is totally ineffective,

believe me I tried it at first!

Then I ‘boiled’ them up in paraffin in the oven not a good move for

domestic harmony, and not recommended unless major rows are high up on your

personal agenda!

It sort of worked, I did plug the bolt holes, used the boxes as bathtubs for the paraffin,

then wrapped them in cooking foil – what more can a guy do to preserve

domestic bliss! Then it was gas mark 4 for a while!

The ensuing smell however was all too pervasive and it didn’t do a lot for the

fragrance of the following meals, but at least it keeps you regular during the

inevitable rows and recriminations!

It worked in the sense that it loosened the crud, but it still takes a

lot of releasing and dumping to deck.

On such a safety note, paraffin is actually quite resistant to burning, unlike petrol it

doesn’t flash, it needs the like of a sustained blow lamp to get it burning.

Getting the softened crud out took a mini-drill with all manner of micro stones, wire

brushes and felt bobs and dental picks were pressed into service.

Even then it didn’t work totally – 2 weeks later I took the ‘cleaned’ cam box and

accidentally knocked it to find a fall of soot! I was staggered by the amount

that fell out, the thought of that lot dropping out on an engine start up is

horrifying!

In retaliation I ended up drilling through the baffles to get access to the

‘crud’ but I can’t recommend this as it upsets the oil vapour flow.

So all in all it’s probably best to leave well alone and not try to

clean up a gummed up cam box. Short of baffle removal I can’t think of a good

way of cleaning these things without risking more than it’s worth.

Much better of course not to have this problem in the first place, regular

oil changes go a long way towards avoiding this problem.

ALAN JONES